Give us a call at (540)775-3117 or e-mail us at info@lr-signs.com

What Is Screen Printing?

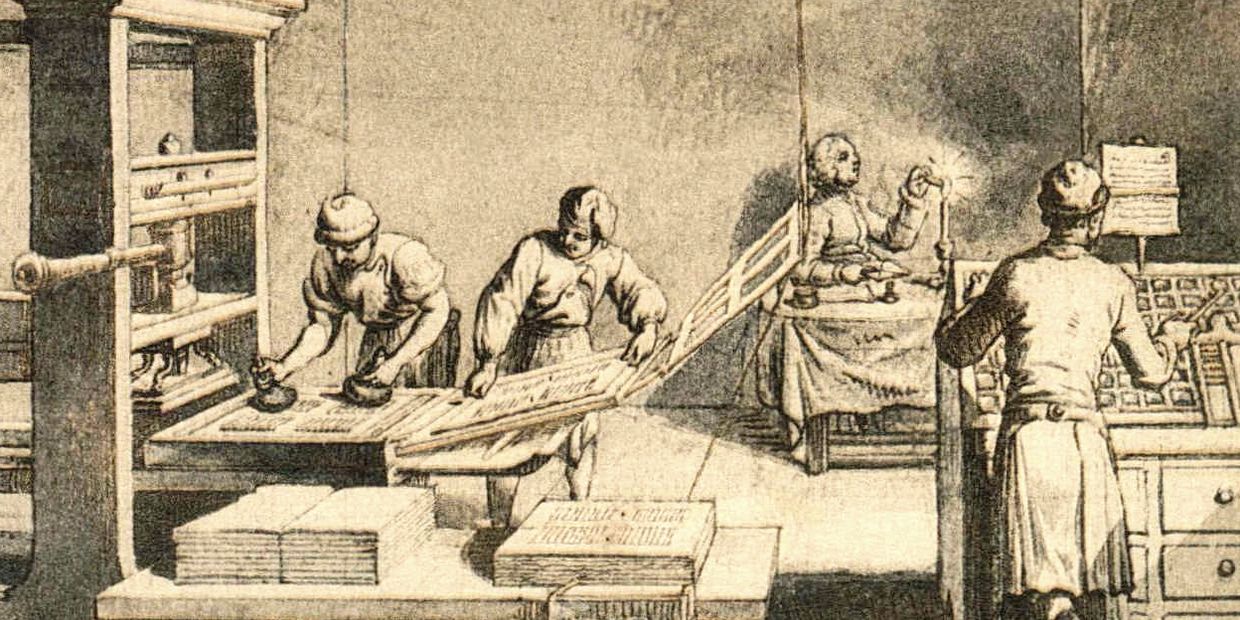

Screen printing, also known as silkscreen printing, is thought to have originated in China during the Song Dynasty (960–1279 AD). Basically, screen printing is a process of printing ink through a stencil. The process has come a long way since the days of the Song Dynasty!

Our Screen Printing Gallery:

View some of our previous jobs and see what is possible with screen printing.

From Design to Transparency

After we have finalized a design with the customer, we digitally print a transparency of each separate color to be used in the design.

A printed transparency that will be used to create a screen.

From Transparency to Screen

Then, through an emulsion process much like how a negative is created with light inside a camera by taking a picture in film photography, each separate color's design is transferred onto a screen, which is already mounted onto a metal frame. If a design requires three colors, three different screens are used.

View the slideshow below to see how three colors, white, grey, and black, come together to form our logo when screenprinted:

A screen that is ready for printing. The yellow areas will be printed.

Example: 3 screens to make a logo

First we have the white shape.

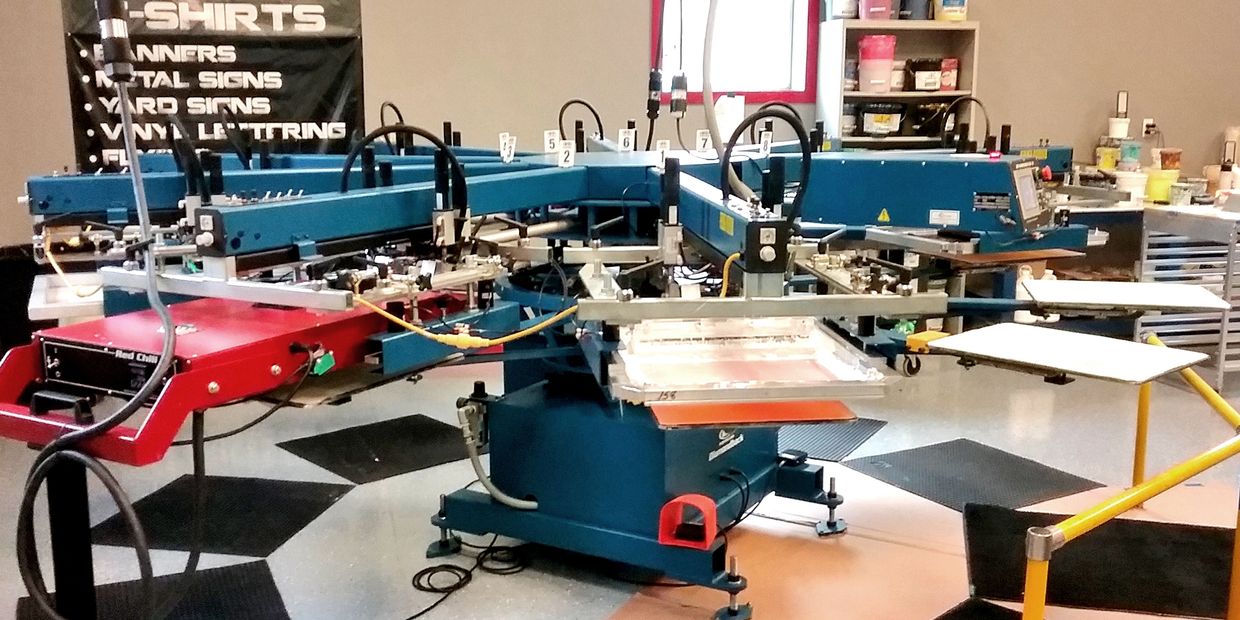

After a screen has been produced for each color used in the design, the screens are fit into separate arms of our printing machine and held in place with pressurized clamps.

A screen mounted to the printing press. The shirt goes on the palette shown underneath.

Different color inks are added to each screen, and the shirts are carefully placed on palettes which are underneath the screens. The palettes are moved under each screen and raised up to meet the screen, in turn, each time a color is printed.

A piece of metal called a flood bar gathers the ink and runs it across the screen, placing it in the mesh of the exposed parts of the screen. Then a squeegee is run across the design and the ink is pushed through only the exposed mesh of the screen onto the shirt, creating a print of the design.

This process is repeated for each color forming a complete design. After printing, each shirt is placed on a conveyor belt which carries them through a dryer which cures the ink

A closer view of a mounted screen with ink loaded; the flood bar is visible in the top-right.

Our automatic printing press, which allows us to print 10 shirts and up to six colors at a time. Shirts are loaded on the pallets which rotate around the machine as each color is printed.

Our manual press which features six pallets. The squeegee is used by hand to load the ink into the exposed parts of the screen, and is then used to press the ink through the screen, onto the shirt .

Our dryer is also shown on the right. This cures the ink on the shirt making the print permanent.

See What Is possible:

Lots to Choose from!

Contact Us

Better yet, see us in person!

We love our customers, so feel free to visit during normal business hours.

Hours

Open today | 09:00 am – 05:00 pm |